Honeycomb paperboard is a kind of interlayer environmental protection material with honeycomb structure, which is made by bonding corrugated base paper into numerous hollow three-dimensional regular hexagon "

paper core" and bonding the surface paper on both sides. Its structural features endow the material with characteristics such as light weight, high strength and recyclability, and it is widely used in packaging, logistics and other fields.

?

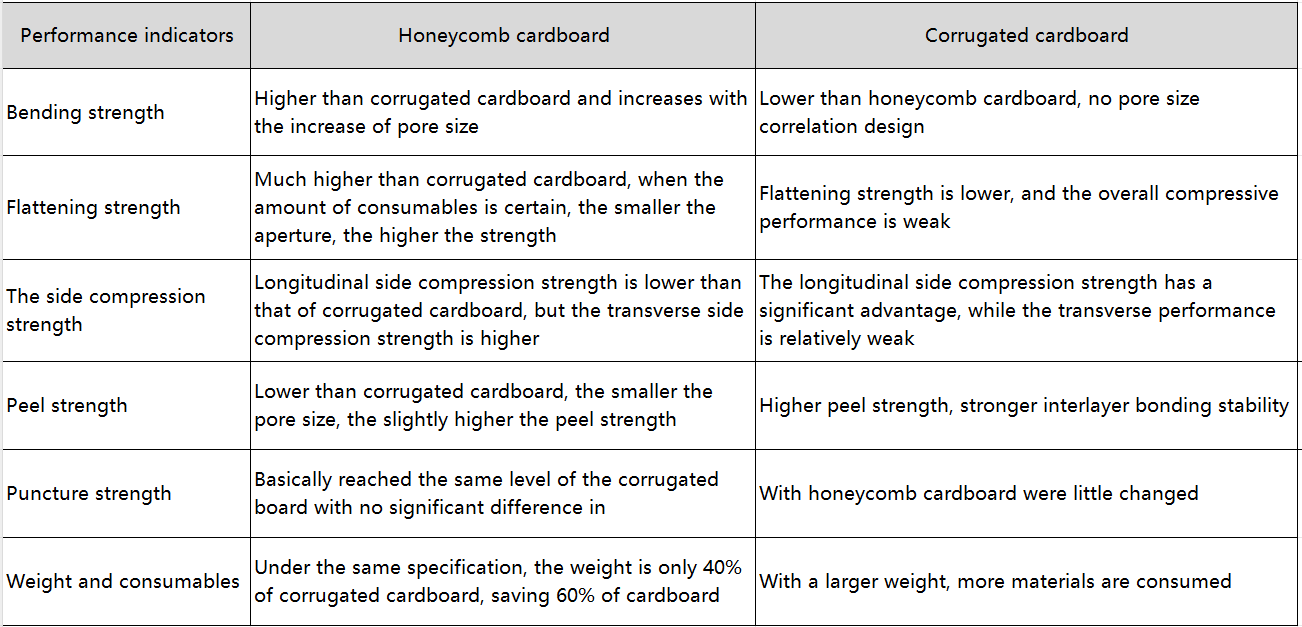

II. Comparison of core performance between honeycomb board and corrugated board

?

III. Core advantages of honeycomb cardboard

Better mechanical properties

- High compressive strength and cushioning performance: The flat compressive strength and bending strength are significantly better than those of corrugated cardboard, making it suitable for heavy object packaging.For example, the empty box can withstand 600 kg of heavy pressure for three months without deformation, and the breakage rate of fragile goods is reduced by 50% to 97% than that of corrugated boxes.

?

- Lightweight design: the weight ratio of the same specification corrugated box is 2:5, which can save 60% of the cardboard material and reduce the transportation cost.

?

Environmental Protection and Sustainability

It adopts recyclable paper materials and has no harmful emissions during the production process, which conforms to the trend of green packaging.

?

Extensive application scenarios

It is suitable for high-value fragile items (such as jade and handicrafts), home appliances, stone and other industries. It can replace wooden crates, reducing weight by 55% to 75%, and its buffering performance is 2 to 8 times higher than that of wooden crates.

?

Structural flexibility

It can be designed as an integral type, a combined type or an integrated bottom support type. Paper corner protectors are pasted at the interfaces for reinforcement, which improves the efficiency of handling and loading/unloading.

?

IV. Development Trends and Challenges

- Market demand growth:Honeycomb paperboard has become the paper industry "smart goods" because of its performance advantages, and the full load operation of the production line is still in short supply, especially in packaging, stone, home appliances and other fields.

?

- Technology integration and innovation:The composite use with corrugated cardboard can complement the advantages, such as corrugated carton as the box body, honeycomb cardboard as the liner, improve the shock resistance, compression and bearing capacity.

?

- Industry coordinated development:The corrugated cardboard industry is mature but has overcapacity. The honeycomb cardboard market has great potential but the scale of enterprises is relatively small. The two need to cooperate in developing new products such as composite cardboard to achieve complementary advantages.

?

V. Summary

Honeycomb cardboard with high strength, lightweight, environmental protection and other advantages, in the field of heavy packaging and high-end buffer gradually replace the traditional materials, and the synergy with corrugated cardboard will become an important direction of future development, both through complementary advantages to promote the upgrading of the packaging industry.